Fokker establishments in the Netherlands 1919-1996

The pre-war years

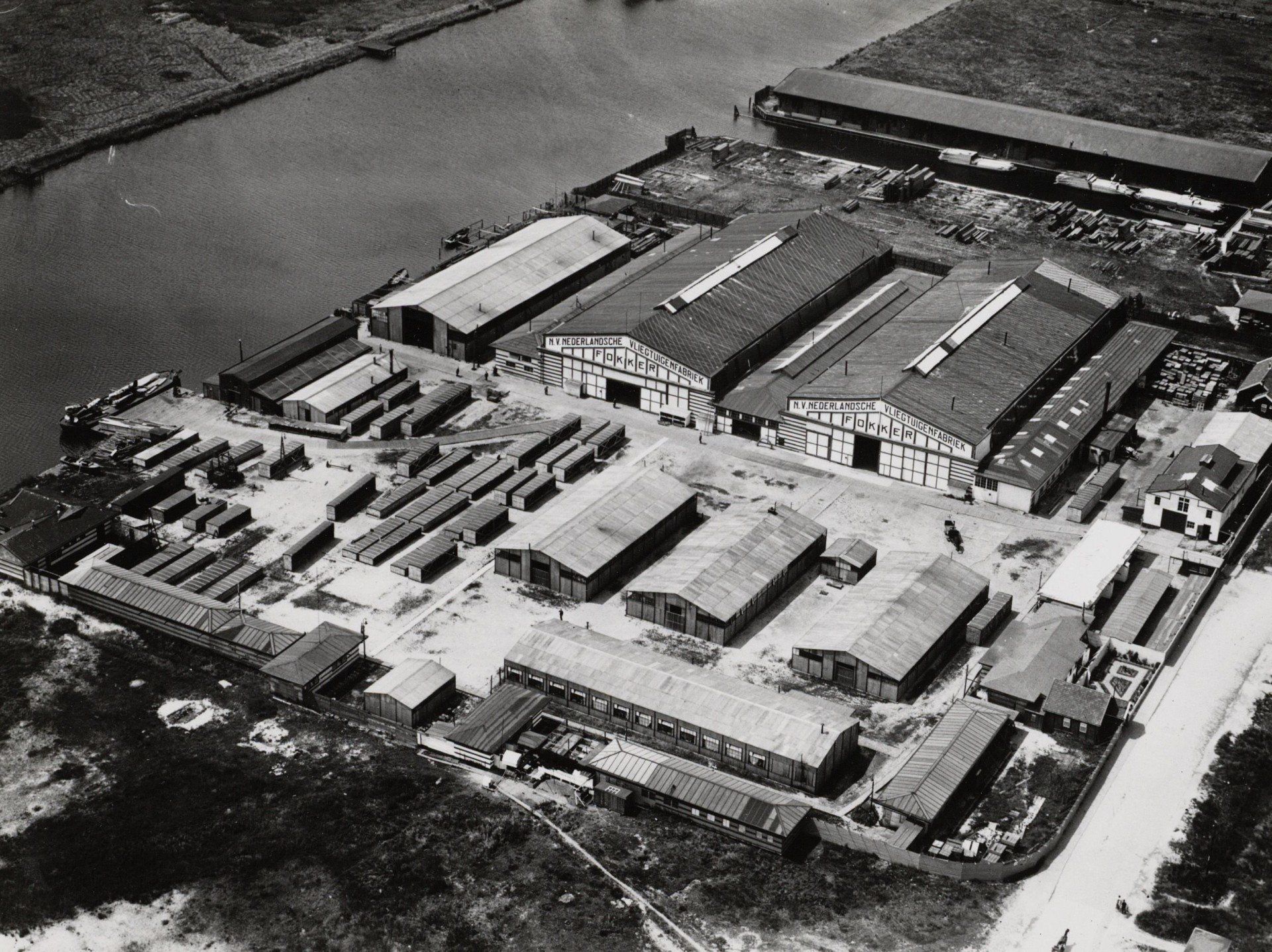

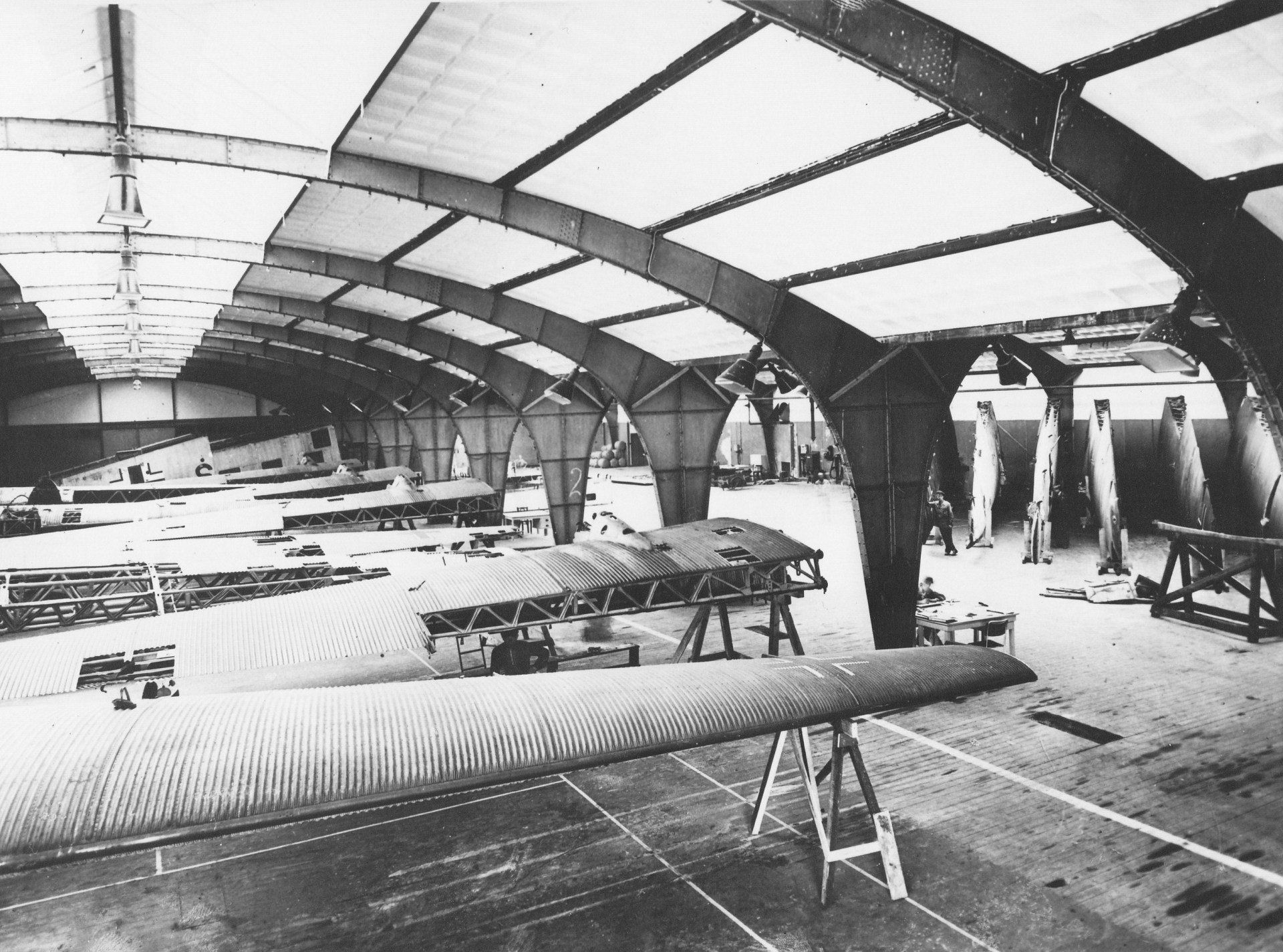

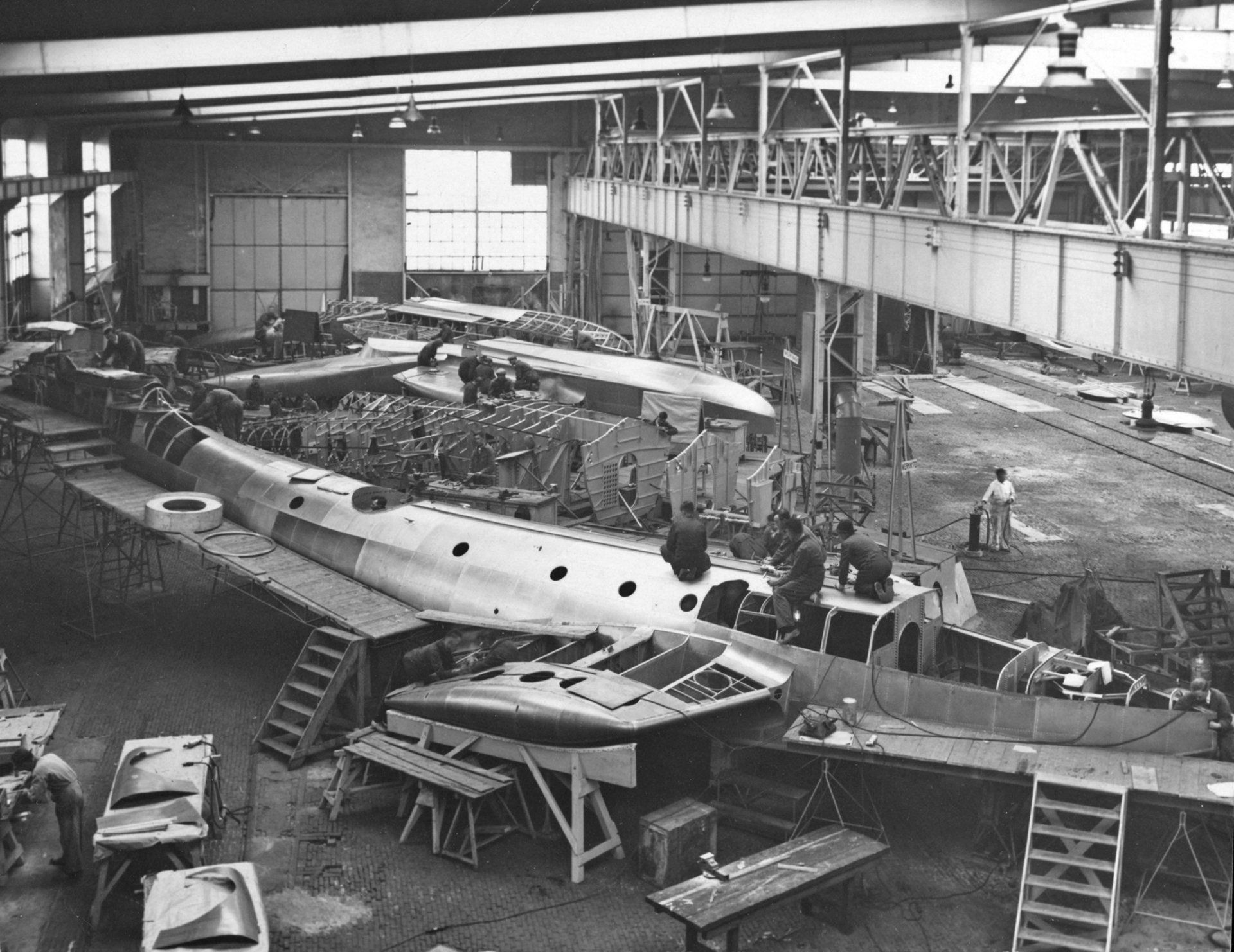

On July 21, 1919, the “NV Nederlandsche Vliegtuigenfabriek” was founded and took over

Fokker moved into Papaverweg 31-33 in Amsterdam-Noord.

The name Fokker was still avoided in the naming of the factory. This was in connection

with the German background of Anthony Fokker in the First World War.

The Aircraft Factory was established in the halls of the ELTA there,

the First Air Traffic Exhibition Amsterdam, which took place there from August 1 to September 14, 1919.

Fokker's seaplanes were tested at the adjacent Schellingwoude air base and

flown into the IJ. This was the air base of the Naval Aviation Service (MLD) on the Amsterdam IJ,

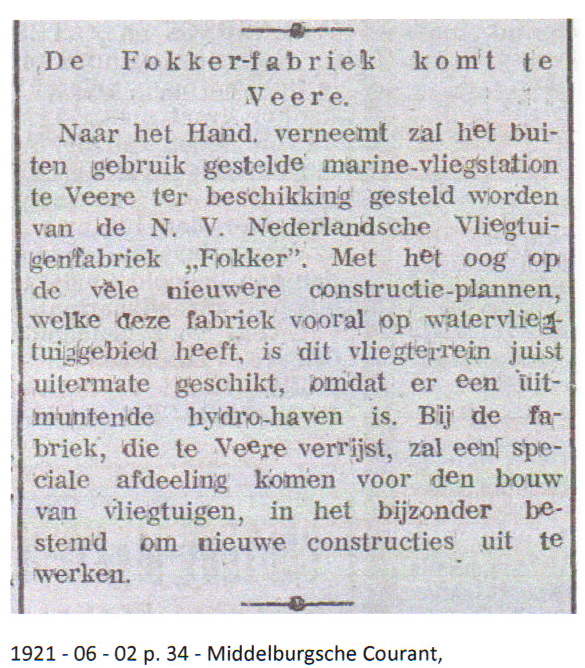

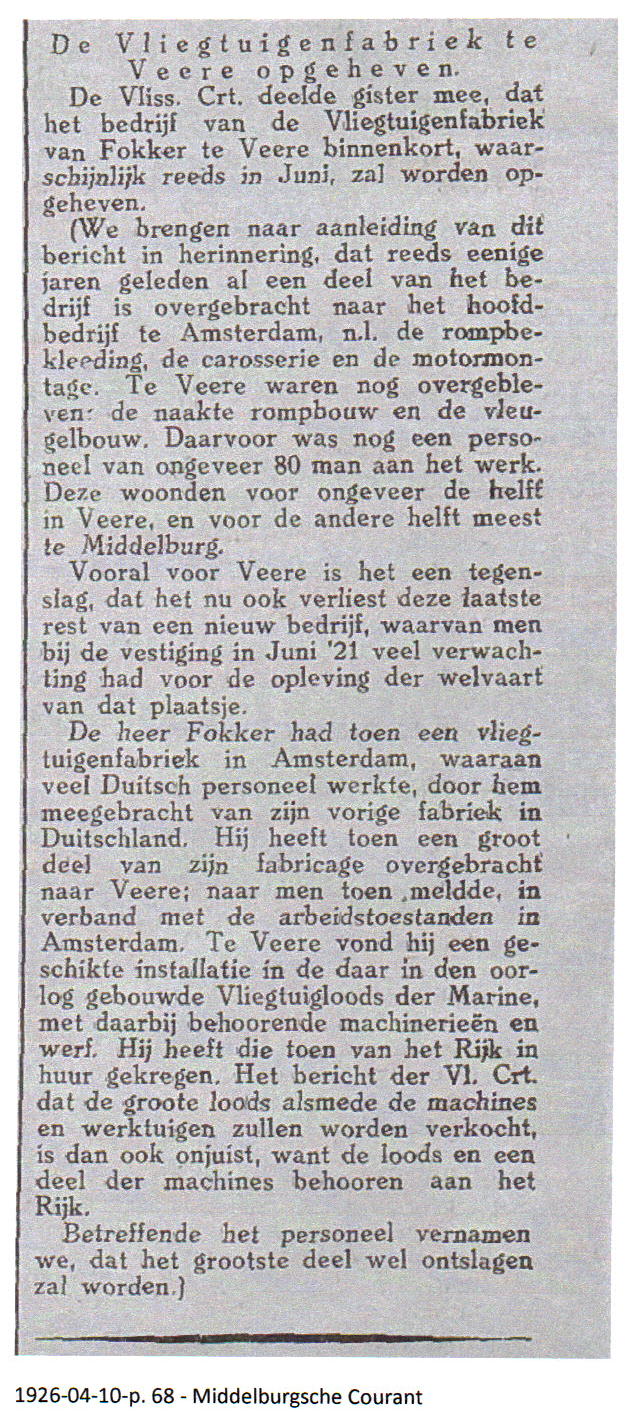

Veere

In May 1921 Fokker also moved into the former air base of the Naval Aviation Service in Veere,

construction of which started in 1916 and was put into use by the MLD on 2-9-1917.

The company was adapted and expanded for Fokker, which meant that production in Veere only really got underway in 1922.

Meanwhile, in 1924, a hangar had been built for Fokker at Schiphol (now Schiphol-Oost).

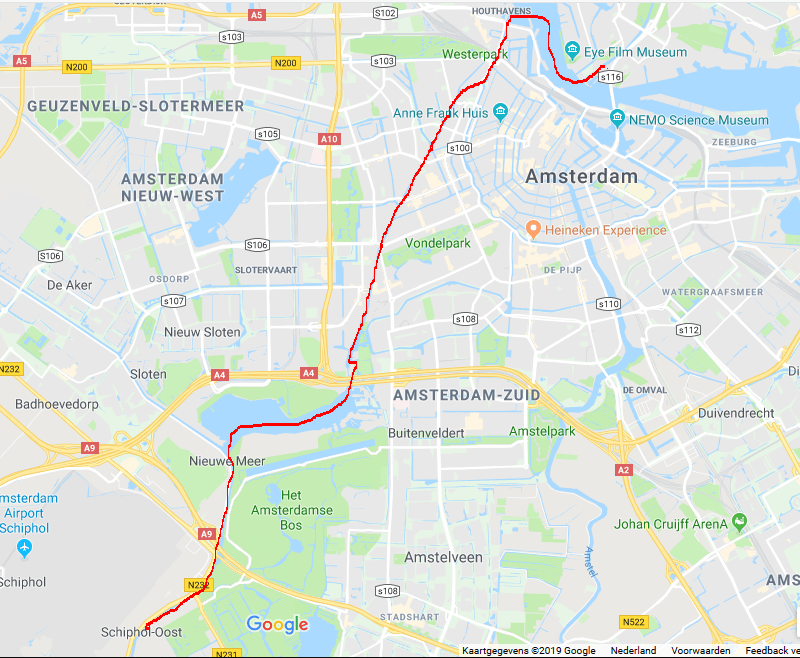

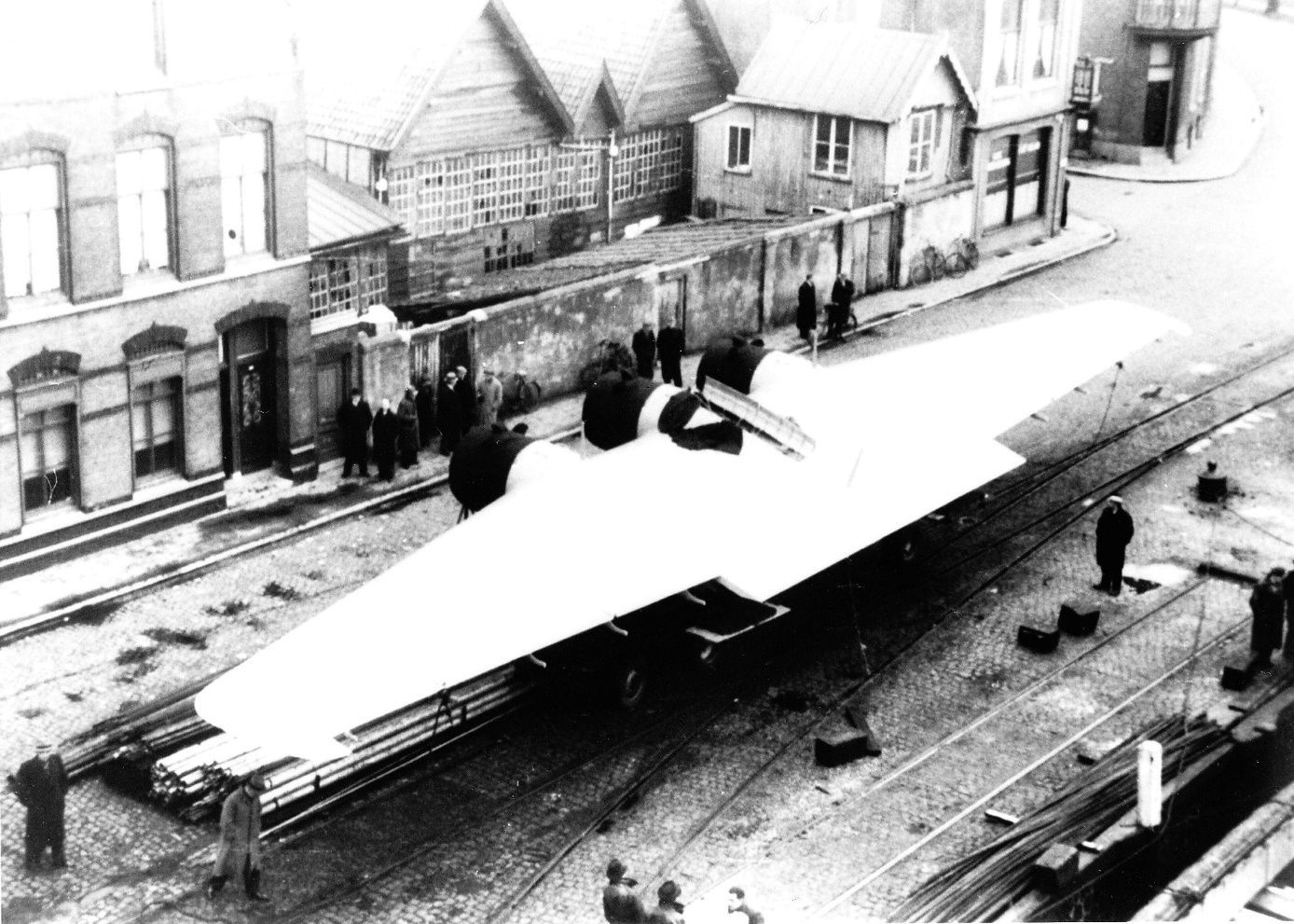

The factory on Papaverweg lacked a runway, so all the aircraft built there were transported by barge across the water, through Amsterdam, to the ring canal in the Haarlemmermeer where Schiphol Airport was located.

In the 1920s and 1930s, Fokker's head office was located at Rokin no. 84 in Amsterdam, and there were also offices at Rokin no. 87 and 92.

In the 1920s, Fokker himself lived in a (then still existing) villa at Roemer Visscherstraat 47 in Amsterdam-Zuid near the Vondelpark.

Before that, he stayed in rented suites at the Hotel de L'Europe on the Amstel and the Carlton Hotel in Amsterdam's Vijzelstraat.

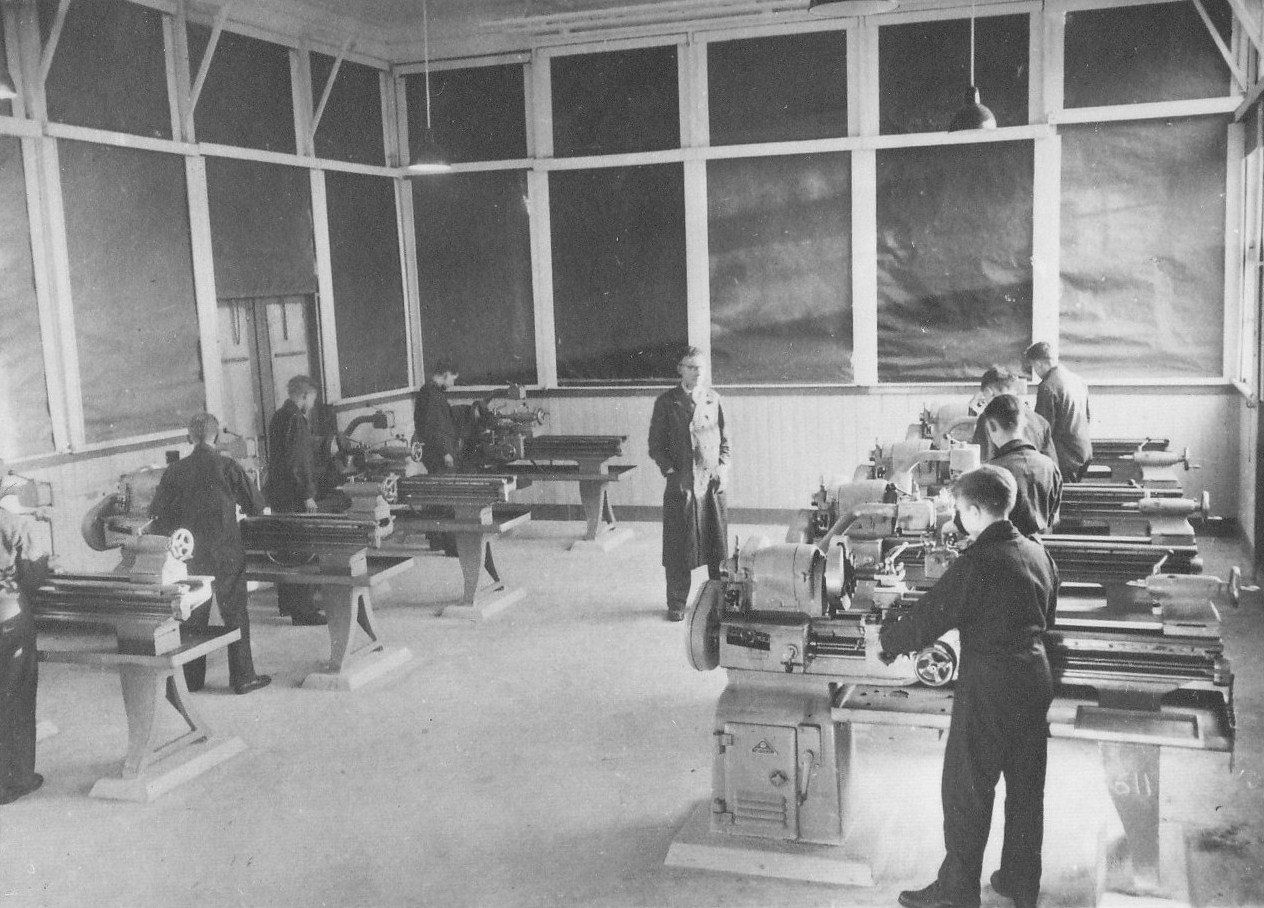

In 1937, Fokker founded a company school, which was located in a building on the Grasweg in Amsterdam-Noord, close to the Fokker factory.

This resulted in a number of departments being housed at the following locations:

• Amsterdam, fashion store Hirsch at Leidseplein no. 29, work preparation, management, sales and personnel affairs.

• Amsterdam, Rokin no. 92, 96 and 102, payroll administration and accounting.

• Amsterdam, Vroom & Dreesmann, Damstraat no. 13, construction office.

• Amsterdam, Boldoot factories, Haarlemmerweg no. 375-377, shipping, parts and materials research.

• Amsterdam, Simplex bicycle factory, Overtoom no. 263-271, tool shop and tool drawing room.

• Edam, Heymeyer Jute Factory, sheet metal work, pressing shop, metalworking, parts construction Arado-196 and Junkers-52.

• Amsterdam, RAI building, Ferdinand Bolstraat no. 155, repair wings Junkers-52.

• Amsterdam, wallpaper factory Rath & Doodeheefver, Duivendrechtsekade no. 54 piece assembly and hull construction Arado-196, final assembly Bücker-181.

• Weesp, bicycle factory Magneet, Groensingel, woodworking, hull construction Bücker-181.

• Helmond, Textile Factory de Wit, control surfaces Junkers-52, wing Arado-196, Motor jacks Junkers-52, fuselage and shell construction Junkers-388.

• Amsterdam, Schellingwoude air base, wing extension and acceptance of Dornier-24 and Arado-196.

• Loosdrecht, Loosdrecht airfield, wing addition and removal of Bücker-181.

• Amsterdam, Dutch Concrete Company, Distelweg, Fokker assembly hall.

• Amsterdam, Coenhaven, Junkers-52 parts production.

• Amsterdam, Oostelijke Handelskade no. 12, Royal Holland Lloyd building, construction office.

For the possible production of the Junkers-388 by Fokker, production space was examined

in North Brabant and Limburg, including at companies in Mook and Heerlen, but production at Fokker did not continue.

After the Second World Warg

At the urging of the government, Fokker formed a joint venture with Aviolanda on January 1, 1947

and the aircraft construction department of the Royal Company de Schelde, the NV Verenigde Vliegtuigenfabriek Fokker io (in formation).

Aviolanda was located in Papendrecht/Dordrecht, the Scheldt in Vlissingen.

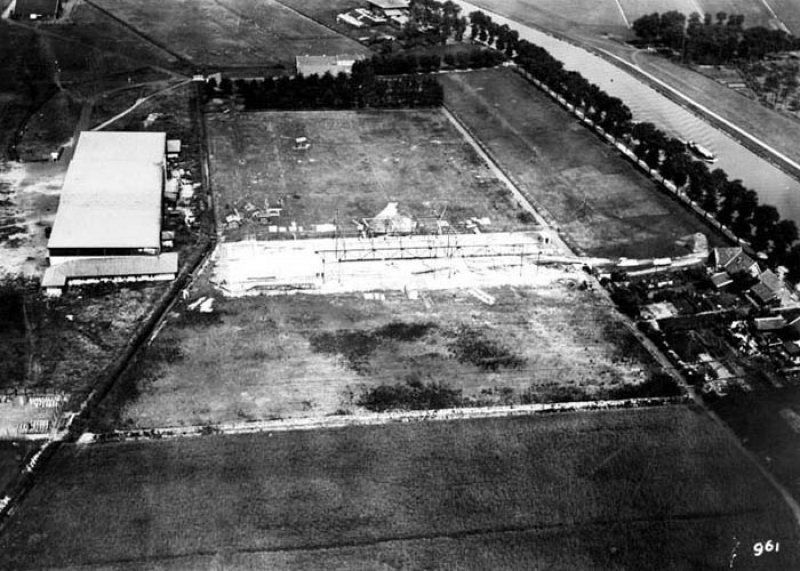

In 1949, a section south of Schiphol (now Schiphol-Oost) in the Haarlemmermeerpolder,

the first pile was driven for a completely new Fokker factory.

In 1951 Fokker moved into this new factory, the factory on Papaverweg

was used for a number of purposes at least until 1955.

In April 1949, Aviolanda and the Scheldt became independent again.

On February 16, 1954, AVIO Diepen became a subsidiary of Fokker.

The Aircraft Trading Company and the repair company of AVIO Diepen were located at Ypenburg airport near The Hague, of which Frits Diepen was director.

On March 1, 1954, Frits Diepen became commercial director at Fokker.

On May 1, 1954, the aircraft construction department of the Royal Company de Schelde now

forever in Fokker.

On December 31, 1967, the Aviolanda branches were also incorporated into the Fokker group.

Not only Papendrecht/Dordrecht but also the Woensdrecht branch, which

meanwhile became part of Aviolanda.

In 1969, the company NV Lichtwerk in Hoogeveen was included in the

Fokker concern, NV Lichtwerk was founded on 18-09-1961.

Both on the Papaverweg and later at Schiphol, Fokker regularly had to deal with

with lack of space. Then space was rented elsewhere for a certain period of time

or were production activities relocated elsewhere.

In the early 1920s and late 1930s, production activities took place in

workshops of Werkspoor in Haarzuilens in Utrecht.

In 1923, among other things, wing construction and at the end of the 1930s G-1 components were built in Haarzuilens

built.

In the 1970s and 1980s, Fokker had storage and warehouse space for the Schiphol location

rented from the Verhoef Company in Aalsmeer.

From the 1970s onwards, the Dutch Fokker locations were designated as follows

with the (main) activities there:

• FBS, Fokker company Schiphol, aircraft end lines, production, delivery and space activities.

• FBD, Fokker company Drechtsteden, including component construction of F-27, F-28, Fokker 50, Fokker 100.

• FBY, Fokker company Ypenburg, plastics company, such as maintenance/conversion of F-27, maintenance of F-104 Starfighter of the Royal Netherlands Air Force.

• FBW, Fokker company Woensdrecht, maintenance/conversion F-28, Fokker 100,

• ELMO, Electrical Installation (wiring), maintenance MLD Atlantic and Neptune.

• FBH, Fokker company Hoogeveen, including component construction, shelter construction.

The main building at Schiphol, building 9, and later building 41, became too small in the 1970s.

The board of directors and other directors were seated there, among others.

Fokker moved into the building of the former Elsevier publishing house in Amsterdam West,

on Krelis Louwenstraat. This became the new head office.

After spending several years in the Elsevier building, the

Fokker head office with management, marketing and sales department, plus other (office) departments

to a larger building in Amsterdam's Bijlmermeer, the America building of the

Atlas office complex on the Hoogoorddreef.

After the bankruptcy of Fokker on 15-3-1996, the companies in Papendrecht and

Woensdrecht was taken over by other companies, Stork/GKN and is still operating (as of 2019).

Jaap Rosen Jacobson first tried to make a fresh start with the company Rekkof, but the curators did not cooperate with his plan.

In 2021 Two years ago he managed to buy two remaining Fokker companies: the maintenance and service companies Fokker Services and Fokker Techniek,

with a total of 650 employees. These two companies were to form the basis of a new Fokker.

The entire article: https://www.volkskrant.nl/economie/idealist-die-bleef-geloven-in-fokker-en-de-productie-van-een-duurzaam-vlieg~b01b1742/